-

1.High crushing ratio and high crushing capacity.

-

2.Low cost and economical.

-

3.Simple structure and long life span of spare parts.

-

4.Customers can choose different types ‘crushing chambers according to the crushing technological process.

Overview

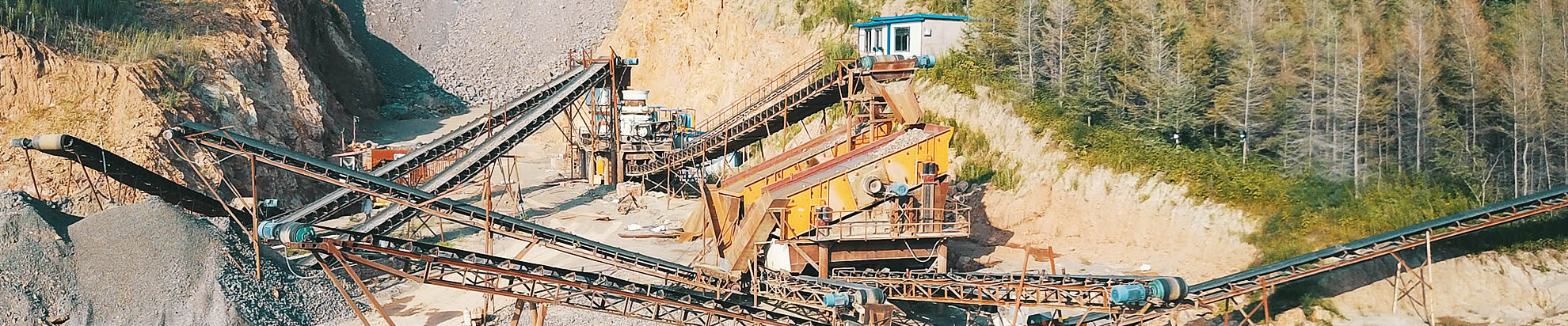

Spring cone crusher is suitable to crush all kinds of ores and rocks with medium-hardness and above. It has features of reliable structure, high efficiency, easy to adjust, economical to use and so on. Spring system plays the role of overload protection, which will enable the exotic materials of steel piece to pass through the crushing chamber without any damage to the machine. It adopts grease seal or water seal to isolate stone powder and lubricants, therefore ensure its reliable operation. According to customer demand, respectively, using standard type (PYB), medium (PYD) for coarse crushing, medium crushing and fine crushing operations.

Working Principle

Cone crusher crushes materials by the working surface between the movable cone and fixed cone. So it is more advanced and efficiency efficient than jaw crusher. The movable cone is supported by spherical bearing and fixed on a hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are driven by the eccentric shaft sleeve together. The eccentric shaft sleeve is driven by horizontal shaft and imbricate gear, and the wheel of the conveyor belt is driven by motor through v-belts. The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, materials are crushed into pieces, when the movable cone leaves, materials is discharged from the discharge hole. The fixed cone can be ascended or descended by adjusting setting to adjust the width of discharge hole, consequently the output size determined adjusted.

Specifications

|

Type |

Max. input (mm) |

Adjusting range of output (mm) |

Capacity (t/h) |

Motor power (kW) |

weight (t) |

Overall dimensions (L×W×H)(mm) |

|

PYB |

600 |

65 |

12-25 |

12-25 |

30(40) |

5 |

2800×1300×1700 |

|

PYD |

35 |

3-15 |

5-23 |

5.5 |

|

PYB |

900 |

115 |

15-50 |

50-90 |

55(75) |

8.8 |

3050×1640×2350 |

|

PYZ |

60 |

5-20 |

20-65 |

8.8 |

|

PYD |

40 |

3-13 |

15-50 |

9 |

|

PYB |

1200 |

145 |

20-50 |

110-200 |

110(150) |

24.7 |

4152×2300×2980 |

|

PYZ |

100 |

8-26 |

50-150 |

25 |

|

PYD |

50 |

3-15 |

18-105 |

25.6 |

|

PYB |

1750 |

215 |

25-60 |

280-480 |

160(220) |

50.3 |

4870×3800×4192 |

|

PYZ |

185 |

10-30 |

115-320 |

50.3 |

|

PYD |

85 |

5-15 |

75-230 |

50.4 |