-

1.The impeller structure adopts latest four ejection openings, which improve the material passing capacity. The crushing efficiency is improved about 20% higher than three ejection openings impeller.

-

2.The impeller parts’ structure and craft are improved. The lifetime of impeller parts is improved about 30-200% longer.

-

3.The drive part adopts special leak proof structure, which prevent the bearing drum from oil leakage. It acquires 2 national patents. The bearing is imported, and reduces the failure of drive system.

-

4.Lifting device is convenient for maintenance.

-

5.Simplified substructure design has excellent performance in avoid the discharge opening jammed by material which water content is over much.

-

6.Adopt "stone-on-stone" crushing method to decrease kinds of wear part, effectively reduced production cost.

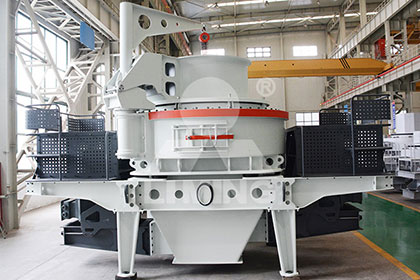

Overview

According to idea support and rich experience, VSI6X Vertical Shaft Impact Crusher adopts latest four ejection openings and special leak proof structure, which prevent the bearing drum from oil leakage. These new designs make the plant more efficient, longer service life and broader range of applications. Besides, VSI6X Vertical Shaft Impact Crusher acquires many national patents as a high-efficiency plant, and it can realize large-scale production in order to meet the country’s requirements of capacity and environment.

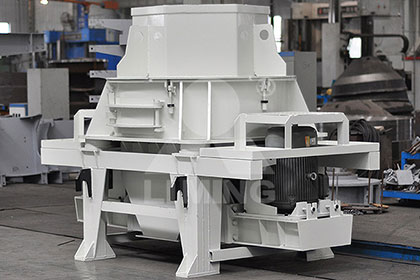

Working Principle

The motor drives the main shaft to make the impeller to rotate at a high speed. The material which entered impeller will speed up and ejected to crushing chamber, and then impact with the material liner that shaped in crushing chamber. In this process, to make the kinetic energy got from speeding up transform to energy need for crushing and shaping. The material will recycle for many times in the crushing chamber. After many times crushing and shaping, by the function of around gas eddy, to achieve constantly crushing and shaping. The final products are discharged from bottom outlet of machine body. This crushing method is "crushing between materials", and it is used for material shaping. Besides, this machine also has another crushing method "crushing between materials and liners". To compare with "crushing between materials", the difference is: After material ejected from impeller, the material will impact with liner installed in crushing chamber. After impacting, the material will discharge from bottom outlet of machine body directly, and it does not recycle many times in crushing chamber. This crushing method is mainly used for crushing (target for large crushing ratio).