-

1. According to the process requirements of the production line, the pedestal type or suspension type installation can be selected, and the installation angle can be selected from 0-10° according to the needs, which significantly improves the processing capacity and screening efficiency.

-

2. Variable frequency motor is used for driving, stepless adjustment of feed quantity, easy to operate and control, more stable startup and adjustment, uniform and accurate feeding, ensuring continuous and stable feeding.

-

3. The handling capacity can be adjusted by adjusting the installation inclination or adjusting the operating speed with optional frequency converter, and the handling capacity can also be adjusted by adjusting the eccentric force of vibration motor.

-

4. Compact structure, small volume, light weight, stable vibration source, strong excitation force, easy to use and maintain.

Overview

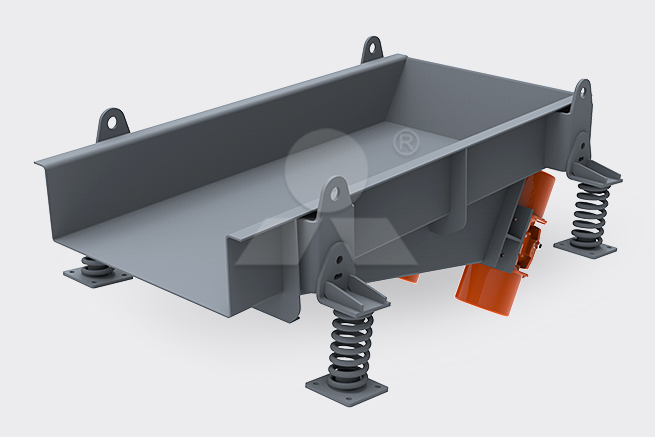

SP Series Vibratory Feeder is a new type of Vibratory Feeder specially designed by Coffeida for the feeding of secondary and tertiary crushers and the feeding of belt conveyor under the regulating yard and silo. Two vibration motors are used as excitation source, mainly used in sand and gravel aggregate, metal mining, coal, chemical industry and other industries. It is driven by variable frequency motor, which makes it more stable to start and adjust, uniform and accurate feeding, and ensures continuous and stable feeding.

Working Principle

During the movement, the material continuously jumps forward at the vibration frequency of the tank body, so that the material is slowly pushed from the feeding end to the discharging end to achieve the purpose of feeding.